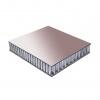

| Item | Specification | Dimentional Tolerence |

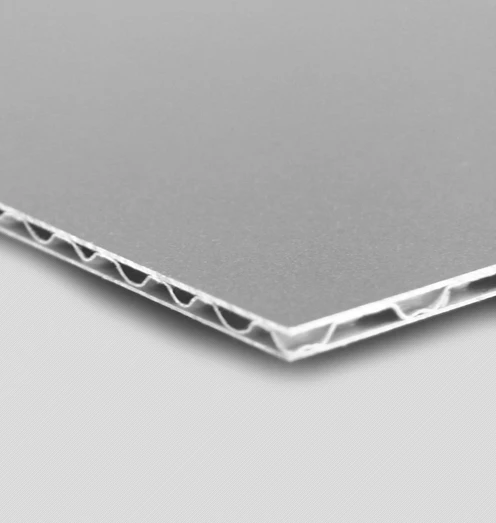

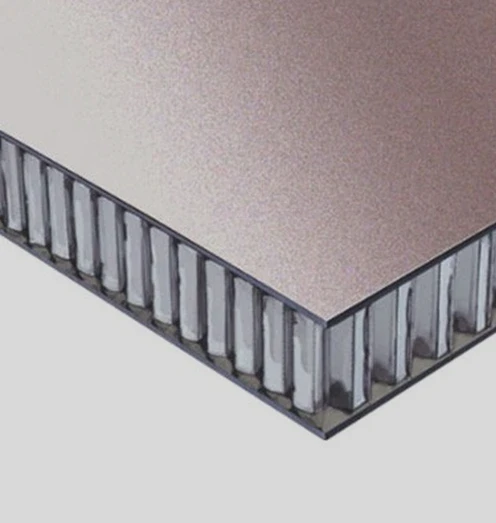

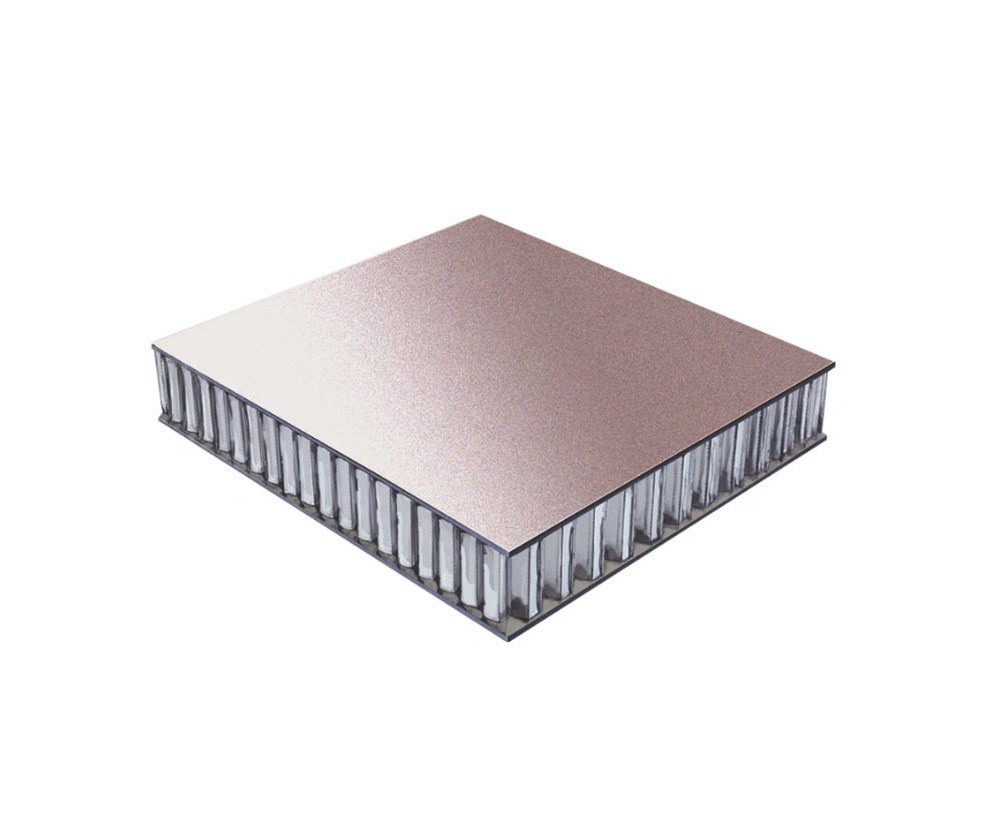

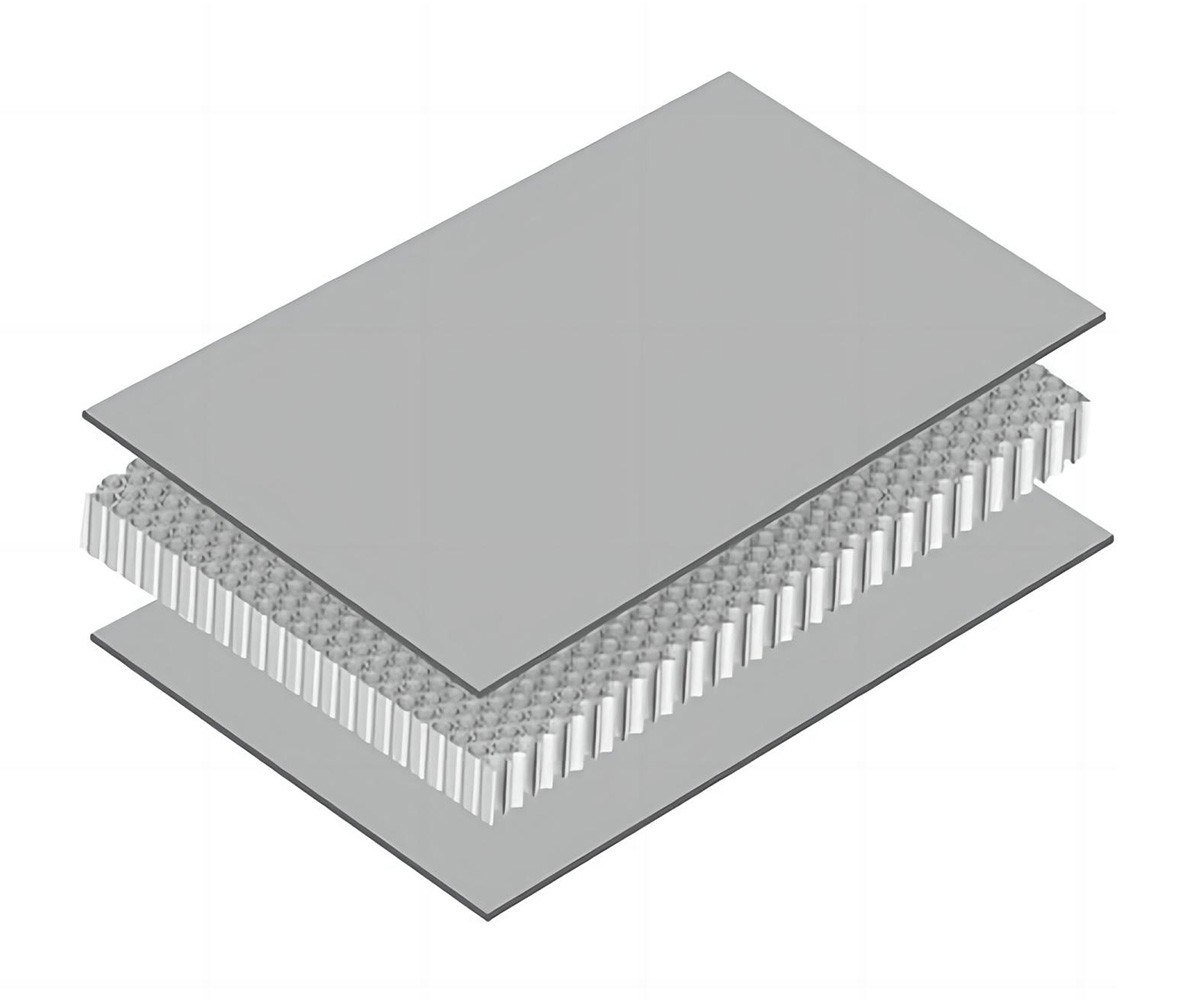

| Thickness | 6~25mm | ±0.2 mm |

| Width | 1250mm,1500mm | ±2 mm |

| Length | 2000mm-6800mm | ±3 ~ ±5 mm |

| Thickness of front sheet | 1.0 mm | ±0.02 mm |

| Thickness of back sheet | 0.5~1 mm | ±0.02 mm |

| Surface Finish | PVDF/NANO/FEVE/HDPE/PE | / |

| Weight [kg/m2] | 4.7~7.3[kg/m2] | / |

SK Color Chart - Standard

SK Color Chart - Standard SK Color Chart Wood Series

SK Color Chart Wood Series SK Color Chart Marbel Series

SK Color Chart Marbel Series SK Color Chart Corten & Concrete Series

SK Color Chart Corten & Concrete Series TDS

TDS EN MSDS Honeycom

EN MSDS Honeycom Unloading and Storage Manual

Unloading and Storage Manual Warranty Certificate

Warranty Certificate